Nanoindenters for Nanoindentation Hardness Testing

Nanoindenters for Nanoindentation Hardness Testing

Nanomechanical testers from KLA Instruments™ provide precise, reliable and repeatable measurements of hardness, Young’s modulus, and other mechanical properties to help you explore new materials, reduce product failures and accelerate your time-to-market. We offer nanoindentation testing tools that range from easy-to-use to a high performance nanoindenter tester to the industry’s highest performance and most versatile nano tensile tester.

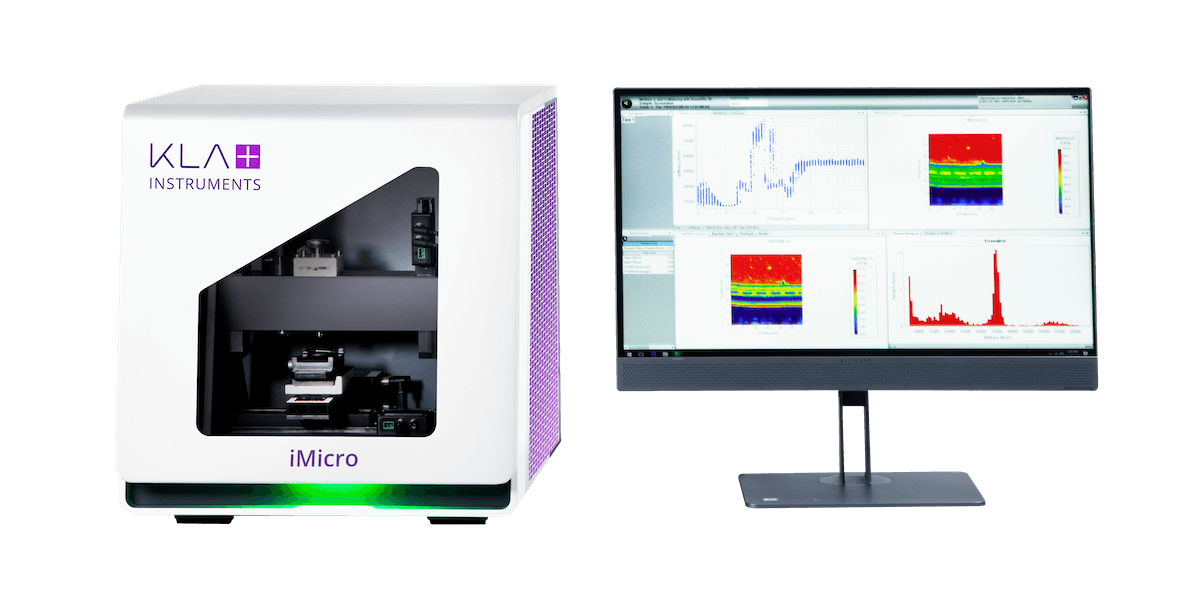

iMicro Nanoindenter

Flexible, user-friendly nanoindenter for modulus, hardness (Oliver-Pharr analysis, ISO 14577), storage and loss modulus, and universal testing. The iMicro nanoindentation instrument is capable of exerting up to 1N of force to test hard materials at higher loads and larger depths. The nanoindentation instrument is fitted with optional actuators for testing of soft materials, tribology, lateral force and other measurements requiring the determination of force and displacement along two axes.

Nano Indenter® G200 Nanoindenter

Fully extendible, production-proven nanoindenter with automated high-throughput hardness measurement capability. With the largest force range in the KLA nanoindenter product family, the Nano Indenter G200 can be used to measure Young’s modulus, hardness, fracture toughness, wear/scratch resistance, coefficient of friction, high-temperature creep response and viscoelastic properties of many types of materials.

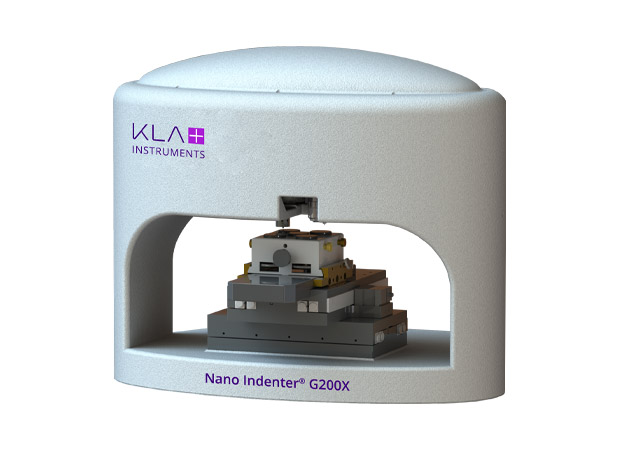

Nano Indenter® G200X Nanoindenter

Industry-leading nanoindenter with a flexible, user-friendly interface for nanoscale mechanical testing. The Nano Indenter G200X uses high-speed controller electronics, an upgraded user interface and advanced InView™ software to enable a variety of optional advanced application modules: frequency-specific testing, quantitative scratch and wear testing, integrated probe-based imaging, high-temperature testing and custom test protocols.

iNano® Nanoindenter

Flexible, user-friendly, low-force nanoindenter that can perform a wide range of nanomechanical tests on metals, ceramics, composites, thin films, coatings, polymers, biomaterials and gels. The accurate nanoindentation instrument is capable of exerting up to 50mN force to test thin films and soft materials.

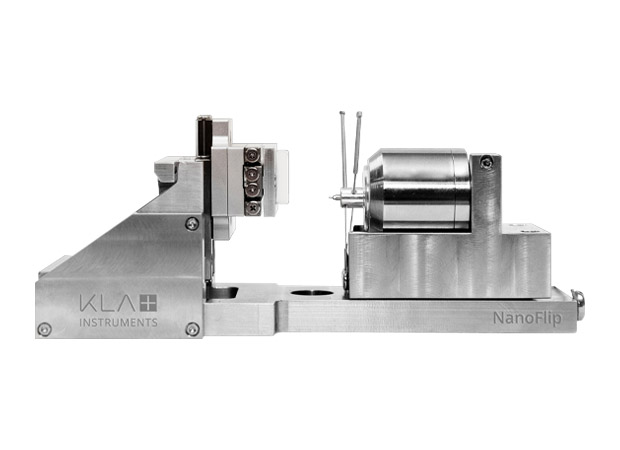

NanoFlip Nanoindenter

Compact, flexible in situ nanomechanical tester for in situ nanoindentation testing inside scanning electron microscopes or gloveboxes or on benchtops. The nanoindenter measures hardness, stiffness and other nanomechanical tests under both vacuum and ambient conditions.

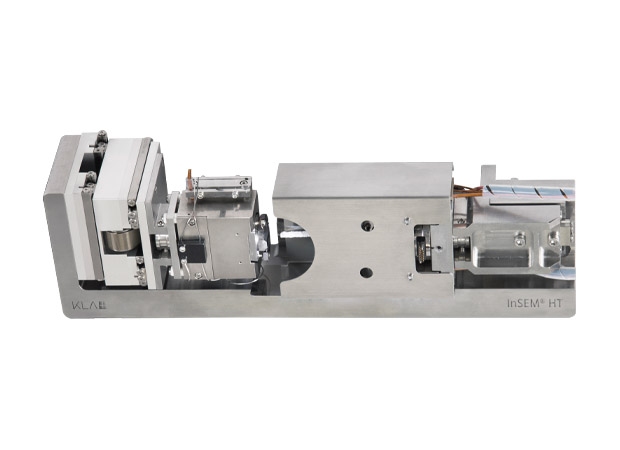

InSEM® HT (High Temperature) Nanoindenter

Highest performance nanoindenter for testing the mechanical properties of small volumes of material under vacuum at temperatures up to 800°C. Real-time deformation data adds to the understanding of material performance at elevated temperatures.

T150 UTM Universal Tensile Tester Machine

Industry’s highest performance and most versatile nano tensile tester, using industry-leading continuous dynamic analysis (CDA) to generate dynamic storage and loss modulus measurements spanning five orders of magnitude.

Looking for thin-film optical metrology?

View MoreTechnical Literature

Browse application notes and technical papers from KLA Instruments Application Engineers and customers, covering a variety of use cases for KLA Instruments products.

Timeline of Nanoindentation Innovation

The field of nanoindentation was co-founded by KLA’s Dr. Warren Oliver almost 40 years ago, and KLA Instruments has continued to foster a culture of innovation. From releasing the first nanoindenter in the market to expanding nanoindentation technology into fast, high-temperature and high strain rate testing, we have continued to develop new static and dynamic measurement types, driving forward the next generation of nanomechanical testing of material hardness.

Receive the latest KLA Instruments news, papers, events, and more

Follow KLA Instruments

Follow KLA Instruments to engage with our experts and learn about our tool applications.